Table of Contents

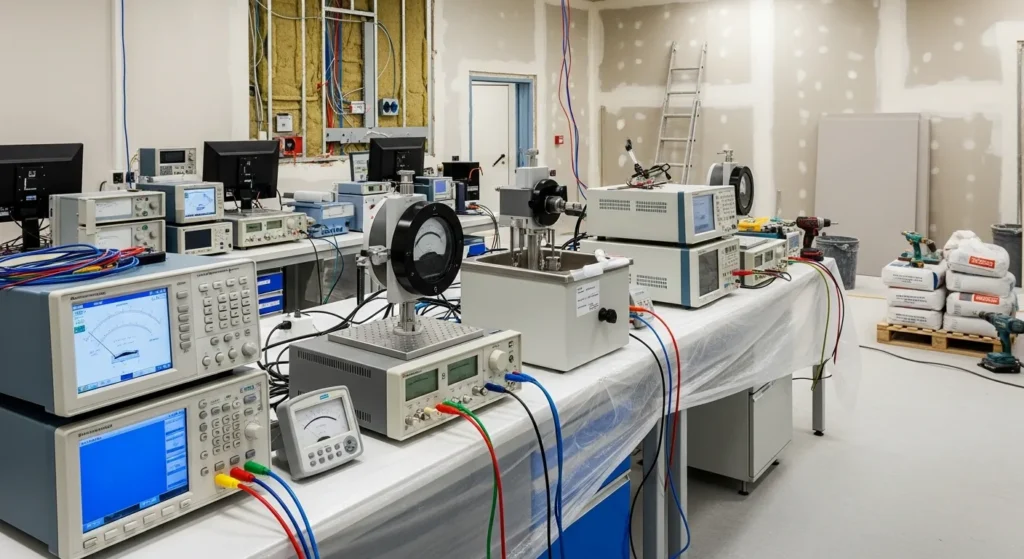

Laboratory equipment maintenance is important to preserve studies correct, secure, and cost-effective. Several studies advise that nicely maintained laboratory equipment makes use of the test significantly enhance reliable and decreases running costs.

This process consists of cleaning, calibration, and preventive tests to keep away from breakdown. A well-maintained plan reduces downtime, extends the device’s life, and ensures compliance with enterprise requirements, making it vital for the success of every laboratory.

Why is laboratory equipment maintenance essential?

Research has constantly shown that laboratory equipment maintenance preserves statistical accuracy and reliability, allowing researchers to depend on their results. The properly-maintained tool lasts for a long time, which enables the laboratories to keep away from costly alternatives. Regularly reduces downtime by way of preventing unpredictable failures and improves average laboratory protection by setting equipment in suitable working conditions. Compliance with ISO, GLP, and GMP requirements often requires documented renovation, making this method crucial for regulatory approval.

Types of Maintenance

preventive maintenance

Preventive maintenance involves regular inspection, calibration, and cleaning to keep equipment in extreme positions. Studies suggest that preventive programs can reduce equipment-related failures by more than 60%, which can save laboratories time and money.

corrective maintenance

A corrective maintenance tool refers to repair after failure. Research suggests that reactive maintenance often leads to higher costs and prolonged downtime than preventive approaches.

Future maintenance

The future maintenance uses data and monitoring tools to forecast possible equipment failures. Modern research supports future strategies as a cost-effective method for high-value devices, reducing unplanned outages.

Calibration and verification

The calibration ensures that the equipment meets performance standards. The verification check confirms the calibration accuracy. Research-supported calibration practices are important for generating reproductive data.

Best Practices for Laboratory Equipment Maintenance

- Follow the manufacturer’s recommendations: Evidence-based studies confirm that the follow-up of OEM guidelines extends life.

- Keep the device clean and properly stored: Control studies show that clean equipment produces more accurate results.

- Train staff on correct use: Training research shows that staff education operators reduce errors by 40%.

- Create a maintenance culture: Research has highlighted that laboratories with a strong maintenance culture experience fewer accidents and lower downtime.

Applying these best practices helps to prolong the equipment and reduce expensive disruption.

Laboratory Equipment Maintenance Preventive Checklist

A research-informed preventive upkeep checklist guarantees that no step is neglected.

Specific responsibilities include:

- Daily: Wipe the surfaces, check for visual damage, and turn the unused device off.

- Weekly: Lubricate the transferring parts, check out the cords and plugs, and take a look at the functionality.

- Monthly: Conduct the calibration test, verify the software program, replace and smooth the internal components.

- Annual: Growing deep cleaning, expert servicing, and trade-out parts.

Environmental probes, inclusive of monitoring of temperature and humidity, are also essential for functioning sensitive gadgets properly.

Calibration of the laboratory system

The calibration laboratory equipment is one of the most essential aspects of renovation. Research indicates that improperly calibrated devices can skew consequences up to 20%.

The calibration procedure commonly entails:

1. Comparing the instrument study with a standard context.

2. Adjusting the system to healthy reference values.

3. Recording results in a calibration log.

It is essential to keep a detailed calibration log for audit and compliance

Laboratory Equipment Maintenance Schedule

Research shows that serial upkeep packages can boost the lifetime by as much as 30%. The agenda needs to mirror the frequency of device use and the producer’s tips. Digital gear and software can automate the reminder, song finished features, and generate reports for compliance purposes.

Record retaining and documentation

Accurate documentation is the cornerstone of laboratory system preservation. Studies recommend that well-recorded protection improves the study and accountability of the log audit.

The required information encompasses:

- Standard operational procedures (SOP): step-by-step guide for protection features.

- Maintenance log: a distinctive document of inspection, cleansing, and repair.

- Calibration Record: Evidence of accuracy verification.

Difference between restore and protection

The repairs are reactive, addressing the breakdown of the gadget after its life. On the other hand, renovation, energetic and designed to prevent issues. Research confirms that preventive applications lessen normal protection prices as compared to reactive cavalry strategies.

Cost of Laboratory Equipment Repair

The cost of repair depends on the type of tool, the severity of damage, and the availability of replacement parts. Studies suggest that frequent repairs are often higher than replacement costs after a certain limit. Services can help control contract and extended warranty costs and provide peace of mind.

Protect your equipment with service coverage

Research indicates that laboratories with preventive service coverage experience fewer unplanned failures and better budget control. Options include preventive maintenance contracts, extended warranties, and complete-service agreements that cover parts and labor.

Laboratory Equipment Maintenance vs. Management

Maintenance specializes in daily care, while management includes a strategic plan and a budget. Research in laboratory control has highlighted that the coordinated plan can lessen total protection costs and enhance standard productivity.

Safety views

Security has to always be a pinnacle priority at some stage in laboratory system protection.

Research shows that laboratories with formal security packages have fewer incidents. It also consists of:

- Wear (gloves, glasses, lab coats)

- Handle Dangerous Equipment

- Follow lockout/tagout techniques earlier than servicing

- Emergency touch records are without difficulty to be had

What can you do to stay safe

All laboratory employees want:

- Get the right training on the usage of the gadget

- Regular inspection before operating contraptions

- Report any malfunction or damage without delay

A studies-based technique to reduce injuries and protect personnel.

Don’t miss our recent post about Tooth Broke in Half Black Inside No Pain.

Maintenance Procedures & Documentation

Each tool needs to have an SOP for each tool kind, precise renovation features, and periods must be outlined. Research shows that persistent poignant data tools enhance credibility. Regular auditing of these records ensures compliance and identifies possibilities to improve the process.

Bonus resource

- Downloadable SOP Template

- Sample preventive upkeep time table

- Calibration log sheet

Maintaining a regular and nicely-written laboratory device maintenance process is the key to lengthy time period achievement in any research environment.

Final thoughts

Laboratory equipment maintenance is supported by using comprehensive studies that display its impact on information integrity, cost management, and safety. Implementing preventive protection, by creating a clean timetable, documenting each movement, and encouraging a lifestyle of care, can significantly lessen the laboratory downtime and improve credibility. Start today by downloading the upkeep template and putting in a structured plan that meets your laboratory’s needs.